The Roland Berger Trend Compendium 2050 covers six megatrends shaping the world between now and 2050.

Supply base reconfiguration in times of constant disruption

Companies must develop a holistic, consistent, and economically feasible plan to stay on course to supply chain stability.

Global supply chains will continue to be disrupted. What started out with the COVID-19 pandemic has manifested the prevailing challenges of a VUCA - volatile, uncertain, complex and ambiguous - world. Challenges are manifold, ranging from geopolitical & economic bloc building, prevailing war zones to ongoing material shortages and increasing sustainability requirements. Today, leaders and organizations must reevaluate and readjust their supply chain networks to become more flexible and adaptive. What is required to stay on course? Before discussing any function specific measures, a top-down view on current geopolitical and economic scenarios is required. Based on such, companies must develop a holistic, consistent, and economically feasible plan to stay on course to supply chain stability.

"The era of pure globalization in a somewhat stable equilibrium of demand and supply is over. Companies need to re-evaluate – if not reconfigure – their supply base to continue operations."

Four steps toward reconfiguration

A company’s overall strategy, as well as the width and depth of risks involved, will shape the scope of the plan and corresponding mitigation. Consider following four key questions.

First, which risks do you want to mitigate? In today’s VUCA world, supply chain disruptions are not singular or occasional events. The ongoing disturbances offer companies an opportunity to reevaluate their current supply chain setup and prioritize the most important challenges and risks. This ultimately reduces complexity amid the ever-changing dynamics.

Second, which regions or countries are exposed to these risks? Reconfiguring a supply chain network in the face of ongoing global tensions requires a holistic understanding of the affected regions and countries. Compare the competitiveness of different countries or regions using an objective and quantifiable approach for risk assessment.

Next, what are your import or export volumes from or into these regions? Only by identifying vulnerabilities in the current supply setup can you sustainably develop options to reduce risk exposure. As well as qualitative impacts, baselining volumes can help determine the quantitative impacts of potential mitigation options.

Lastly, how deep into the value chain do you want or need to go? Reevaluate your current supplier base and look for additional potential suppliers that can cater to your current and future requirements. Understand and compare the current tier-N supplier network to assess potential risks.

Building a resilient supply base

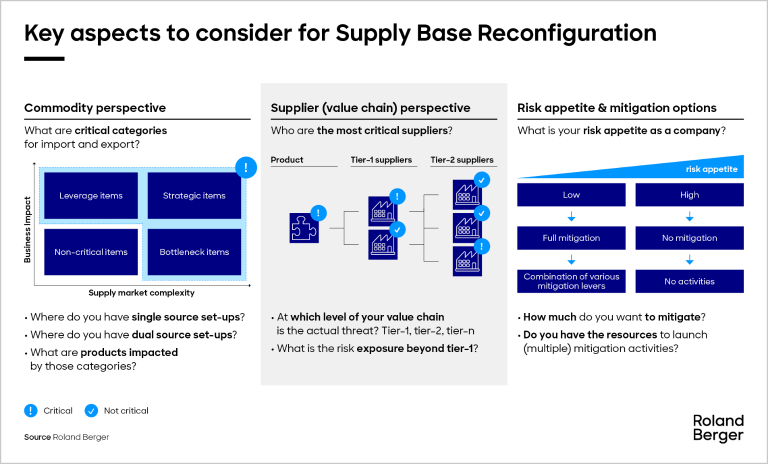

Recent supply chain disruptions are giving companies the unique opportunity – and necessity – to reconfigure their supply base after more than 30 years of globalization. Companies need to think about how they can become more adaptive, flexible, and resilient in their supply chain setup. Three key aspects come into play when reconfiguring the supply base:

- Commodity perspective: Supply of commodities from complex markets with a high business impact may require reconfiguration. Sourcing strategy (e.g., single source, dual source) and the commodity’s impact on current and future business (e.g., product portfolio, value stream) determine the commodity’s risk score. Mapping suppliers and parts at risk with the corresponding business volume is vital for sustainable security.

- Supplier (value chain) perspective: Understanding direct suppliers and the underlying supply network, from tier 1 to tier N, lies at the heart of any supply base reconfiguration. Dependencies beyond tier 1 are crucial in a holistic supply risk assessment. Only when mapping the value stream and analyzing its impact on current and future business can you determine which products might be at risk with the current supply base and require reconfiguration.

- Risk appetite and mitigation options: A company’s risk appetite and strategy will determine the level of mitigation and corresponding resources needed. Mitigation is based on the business at risk per product and the general or specific resilience goals. The commodity and supplier perspectives act as a starting point to develop resilience clusters, which contain mitigation options and are aligned with cross-functional requirements.

Our approach to supply base reconfiguration requires an assessment of a company’s commodities and tier 1 & 2 suppliers as well as a strategic decision regarding its resilience aims. Analyzing and understanding the commodity and supplier landscape act as the foundations for shaping mitigation measures. Depending on resilience goals for the products and business at risk, suitable levers can range from no mitigation to a temporary or full mitigation. Potential actions include buffer stocks, strategic partnerships with new suppliers, and make-or-buy decisions.

It's only with a holistic, consistent, and economically feasible plan that leaders can develop and implement a clear roadmap for supply base reconfiguration. In today’s VUCA world, taking this action is an increasingly important step to defending and maintaining your company’s competitive advantage.

Conclusion

Supply chain disruptions are set to prevail, requiring a paradigm shift in supply base definition. A clearer, more adaptive overview is needed. Supply decisions require a thorough understanding of the commodity as well as a detailed insight into the supply network beyond tier 1. Companies must develop a holistic, consistent, and economically feasible plan to mitigate risk and stay on course to achieve supply chain stability.

Would you like to find out how our supply base reconfiguration toolkit can help create greater supply chain stability amid today’s uncertainty? Our experts will be happy to help you in one of our free “power hours.”

Register now to receive regular insights into our Operations topics.