Roland Berger advises the aerospace, defense and security industries. We support OEMs, suppliers, agencies and investors.

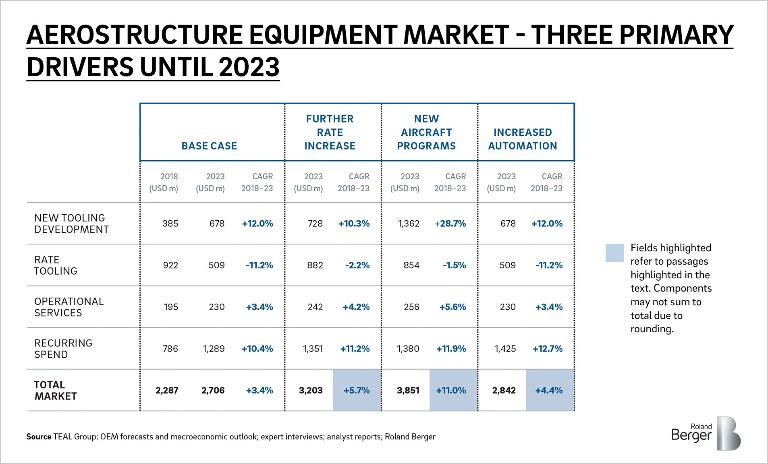

Aerostructure tooling market: Automation the decisive factor

![{[downloads[language].preview]}](https://www.rolandberger.com/publications/publication_image/Roland_Berger_Study_438_Aerostructure_Equipment_Market_Cover_download_preview.jpg)

The study "Hope on the horizon" provides an optimistic outlook for the development of the aerostructure equipment market. Suppliers should invest into automation.