Supporting packaging companies, converters and equipment providers to navigate the rapidly changing packaging and processing market.

Partnering in the processing and packaging equipment industry

The key to meeting the new demand for integrated solutions

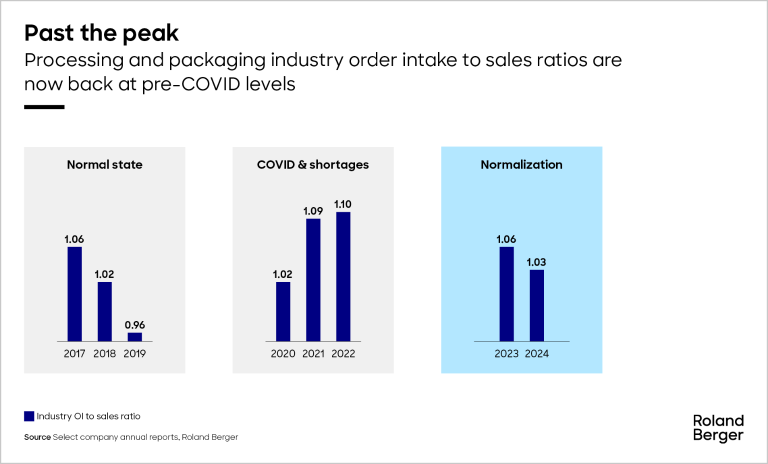

In today’s rapidly evolving processing and packaging (P&P) equipment market, customer expectations are undergoing a fundamental shift. While the post-COVID surge in orders has subsided, it left behind a transformed industry landscape. Buyers are no longer satisfied with fragmented or single-product solutions; they want partners who can provide fully integrated, one-stop-shop offerings that address digitalization, technology, and process chain needs.

""Partnerships aren’t just about sharing resources – they’re about unlocking new opportunities that no single player could achieve alone.""

This presents a serious challenge for many suppliers. Smaller players, in particular, may lack the scale, portfolio breadth, or financial resources to meet these demands on their own. Even larger players must continuously innovate and expand their capabilities to stay ahead of competitors in a market where differentiation is becoming harder. Thus, strategic partnering is emerging as the most effective answer.

Why partnerships matter more than ever

Partnerships allow companies to fill capability gaps, share risks, and strengthen their overall competitiveness. By joining forces, even smaller manufacturers can reach large clients, enter new markets, and innovate faster.

Our research shows that the strongest partnerships are formed along three dimensions of the industry:

- Digitalization – Bringing in AI, IoT, and predictive maintenance to create smarter production systems.

- Technology – Expanding product portfolios with complementary engineering or automation solutions.

- Process Chain – Covering missing steps to offer customers complete lifecycle solutions, from recycling to packaging.

For example, some manufacturers are collaborating with cloud providers to embed digital intelligence into equipment, while others work with robotics specialists to co-develop fully automated end-of-line packaging systems. These collaborations not only enhance customer offerings but also open doors to entirely new application areas.

Our analysis of more than 120 partnerships reveals distinct patterns across company sizes.

- Smaller firms (<€500m sales) focus heavily on process-based partnerships to compensate for limited portfolios

- Medium-sized players (€500m–1.5bn) often emphasize technology collaborations to stay competitive and drive innovation

- Large firms (>€1.5bn) form targeted partnerships with niche players, particularly in process areas, while maintaining strong in-house digital and technology capabilities.

Interestingly, medium and large firms average 6–6.5 partnerships each, compared to just under four for smaller companies. This “partnership gap” underlines how scale makes it easier to pursue multiple collaborations, especially in digitalization, where custom solutions require significant resources.

Innovation through collaboration

- Technology case: A global food and consumer goods equipment provider partnered with a robotics company to co-develop integrated high-speed end-of-line packaging systems. This strengthened both companies’ market presence and opened up new applications.

- Digitalization case: A leading P&P solutions provider in food and beverage joined forces with a major enterprise software company. Together, they created a manufacturing execution ecosystem that digitalizes entire production lines, adding tangible value for customers and setting new industry standards.

These examples demonstrate that partnerships are not just cost-saving measures—they are catalysts for growth, innovation, and long-term resilience.

How to build the right partnership

Forming a successful partnership is not straightforward. It requires a structured, purpose-driven approach:

- Define a clear target picture – What gaps do you need to close? What value do you want to add for customers?

- Identify potential partners – Screen candidates by market access, technology, and governance fit.

- Choose the right model – Options range from strategic alliances and joint development projects to licensing agreements.

- Align stakeholders early – Secure buy-in from boards, shareholders, and other stakeholders to avoid misalignment.

Ultimately, the best partnerships are those that deliver mutual value, transparent communication, and a clear division of roles.

Ready to learn more?

Get detailed insights, case studies, and our step-by-step guide to forming successful partnerships in the P&P industry. Fill in the form below to access the full report.

Register now to access the full study and explore "Partnering in the

processing and packaging equipment industry". Furthermore, you get regular news and updates directly in your inbox.

_person_320.png?v=770441)