Digital design offers many possibilities that may disrupt traditional processes.

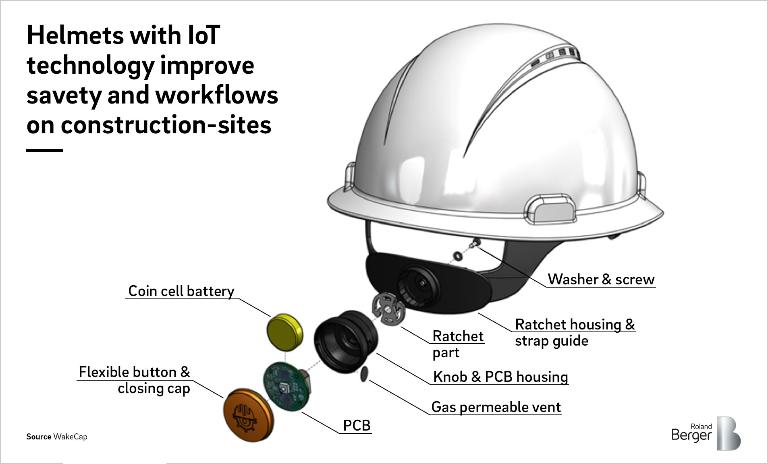

Introducing helmets with IoT technologies for construction sites

Start-up from Dubai about to increase safety and improve workflows in the building industry

"We aim to disrupt the construction industry without disrupting the construction work."

Construction sites change rapidly. This makes it all the more important that everyone involved is always up to date. In most cases, the necessary infrastructure is still lacking. The Dubai based start-up WakeCap has developed a helmet that generates and transmits data based on the Internet of Things (IoT). This significantly increases safety on construction sites. In addition, construction processes can be better coordinated. In this interview, COO and Co-founder Ishita Sood Kochhar discusses innovation, initial market successes and planned pilot projects.

This interview is part of the series "Construction Start-up Radar" .

How will the construction industry develop in the near future?

Ishita Sood Kochhar: Digitalization increases productivity. Construction productivity has been lagging behind other industries and reports have shown that the usage of technologies in the field continues to be the primary obstacle to getting the long-promised benefits of advanced systems. Previous solutions demanded time and attention from the users without clearly providing value, which eventually caused workers to reject these technologies. Construction productivity cannot be improved unless it is correctly measured — and that measurement is acted upon for improvement.

The Internet of Things (IoT) is playing a key role in the revolution of the construction industry and related products. New and innovative construction products equipped with low costs, low power sensors are providing companies with information which in turn is being used to enhance processes, improve safety, reduce costs and increase profitability.

The industry has not yet embraced new digital technologies that need up-front investment, even if the long-term benefits are significant. By 2020, the construction industry should adopt to technologies that ensure safer environments to work at and promote productivity.

What are the strengths of your company?

Kochhar: We connect workers at the construction sites to get real-time field data to make better decisions and gain visibility on the project.

Our strength lies in our technology itself. The solution is seamless, scalable and easy to integrate at any construction site. There is no dependency on the worker in any form to maintain the hardware as the sensors are integrated in to the mandatory to wear safety helmet. The issue of achieving a stable connection at the site is one of the hardest goals and we solve this by using a mesh network technology – wireless connection through beacons – to offer stable connection without relying on power, GPS or internet.

By implementing WakeCap’s technology, the electronic component is equipped with a buzzer and a panic button to facilitate two-way alert system between the workers and a safety manager. In case of an emergency incident, each worker is simultaneously alerted with a loud buzzer, as soon as a worker hears a sound, he presses the button on the knob of the helmet to acknowledge and notify that, he heard the alarm. He then moves to a safe zone. The safety officer has an access to a dashboard, where he can check who is still stuck at the site in real-time and efficiently improve the response time towards a worker who is still stuck. Since we know the location of each worker, we can administer a faster response and an effective evacuation.

What is your vision for the years to come?

Kochhar: Our solution can also be adapted to other sectors like the mining or the petroleum industries. We plan to roll out more productivity features in the future such as tracking-tags for equipment and machinery on working sites where the dynamic environment demands real-time knowledge of all the moving parts. We also plan to leverage partnerships with real-estate developers and government entities in the Gulf region, especially those with an influence over portfolios of subcontractors and projects. These are usually government entities. At the same time, we will be expanding to the US and the European Market as well.

How would you describe your business model?

Kochhar: Our products and services are offered on a weekly, monthly or annually subscription bases. We would charge a one-time fee for the helmets and then a subscription fee based on the number of workers, the construction site and the desired features. We quote the price on a case-by-case basis and provide companies with the accompanying ROI calculations to help them make their decision.

WakeCap has its first major customer and partner – one of the largest construction companies in the MENA region.

What is the financial basis of your company?

Kochhar: WakeCap has secured its seed round of $1.6M from a group of global investors including a leading construction industry player.

As a startup, what is your next goal? What partners do you need?

Kochhar: We would like to partner with more construction companies to run successful pilots projects, with software solution providers to help integrate our solution with their existing technology.

Who are your main clients?

Kochhar: Construction companies and real estate developers – at the moment.

When you talk to potential customers – what challenges do they describe?

Kochhar: 98% of construction projects are incurring cost overruns or delays mostly due to the lack of connectivity, slow information sharing and a lack of automation on site. Today, field engineers spend weeks just to collect the data needed to conduct basic productivity analysis. By the time data becomes available, the site condition has changed, and improvement ideas are already obsolete due to the dynamic nature of construction sites.

What options do you offer to potential clients to face their challenges?

Kochhar: The advantages of joining a pilot project are that the clients get an early access to the technology before it is available in the market and they test it within their site to get the expected results. Pilot projects are offered at a subsidized price to make it a win-win situation for both WakeCap and the client.

What prerequisites do your clients need to bring?

Kochhar: We need information about the site, like the number of workers to be connected, the size of the site and the number of floors and the duration of the project. Once we get the details, we set-up milestones to be achieved in the project and start the installation and the integration.

Name: Ishita Sood Kochhar

E-mail: [email protected]

Company: WakeCap technologies Inc

Website:

www.wakecap.com

Year of foundation: 2017

Number of employees: 11

Headquarters (location): Dubai, United Arab Emirates, incorporated in USA

Stay up-to-date with the newest happenings in the world of digital construction by signing up for our monthly newsletter. Get news on our current featured start-up and the latest relevant updates delivered straight to your inbox.